1/3

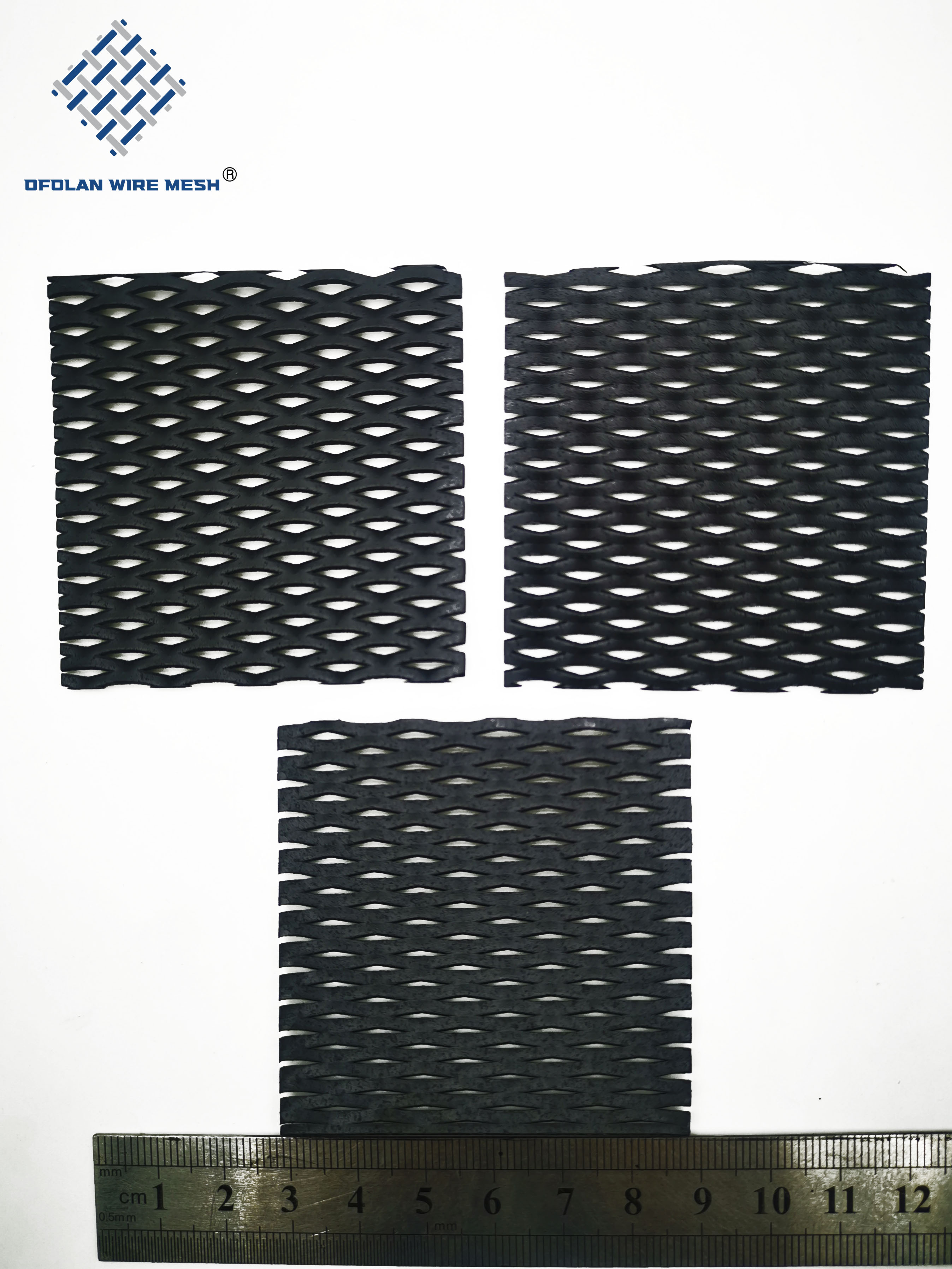

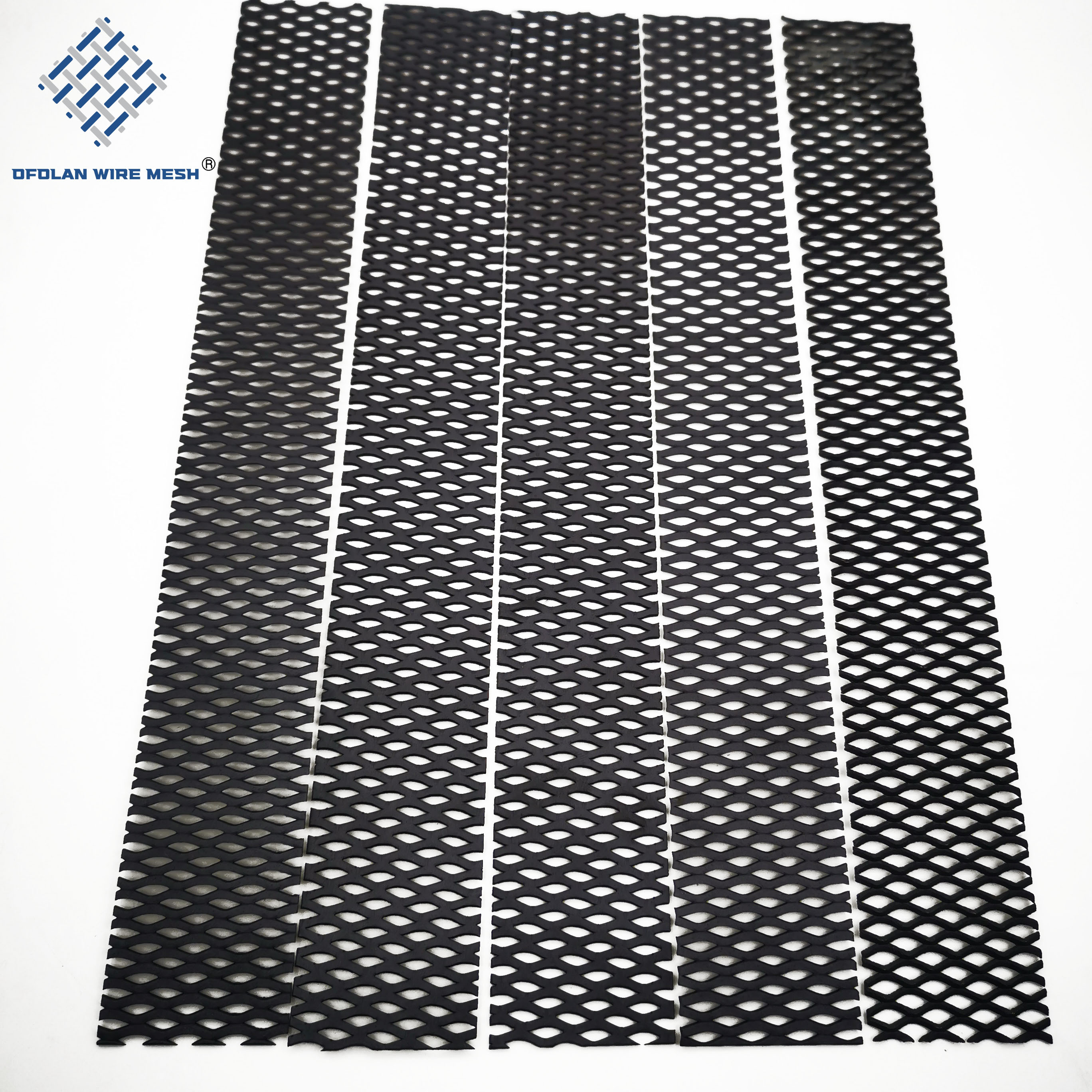

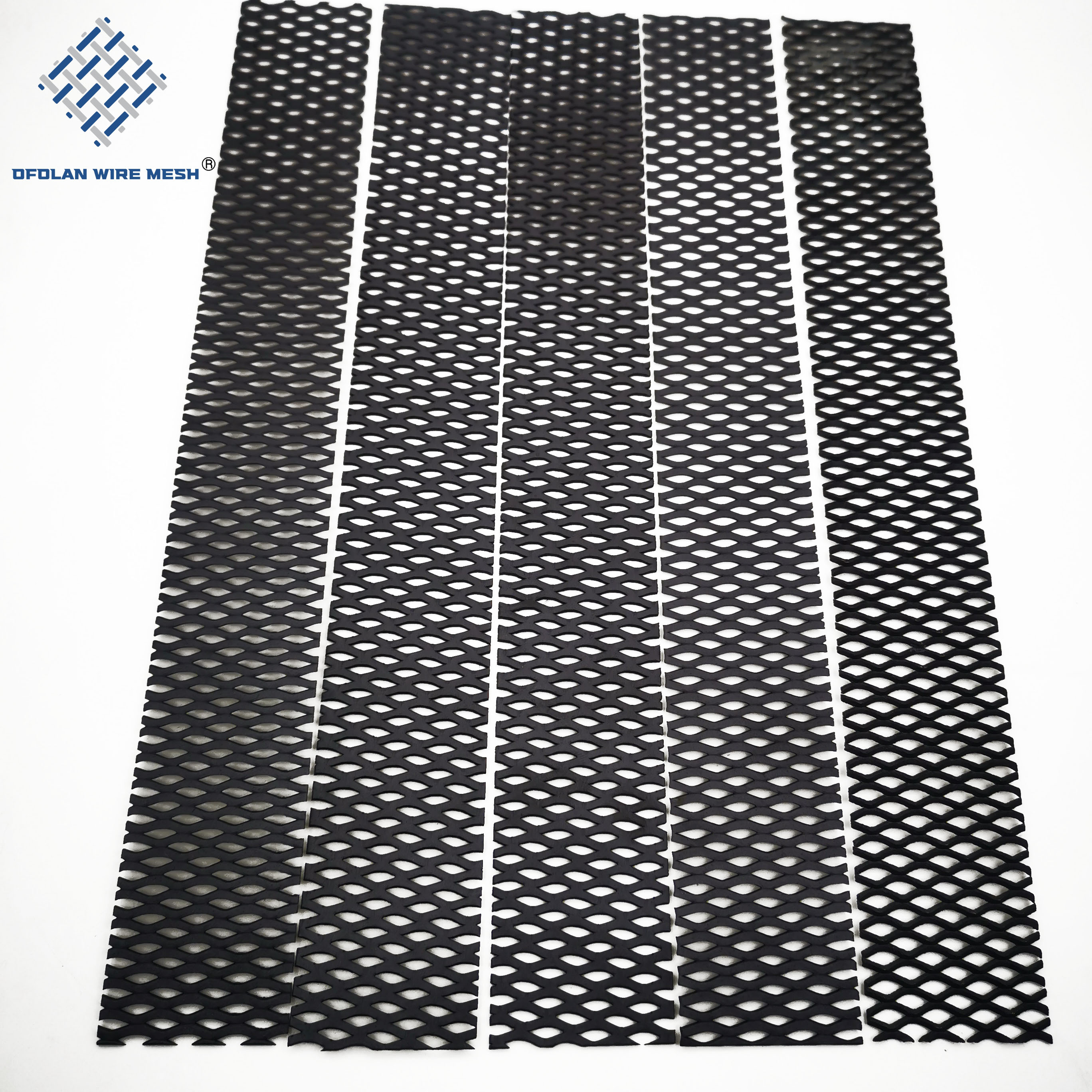

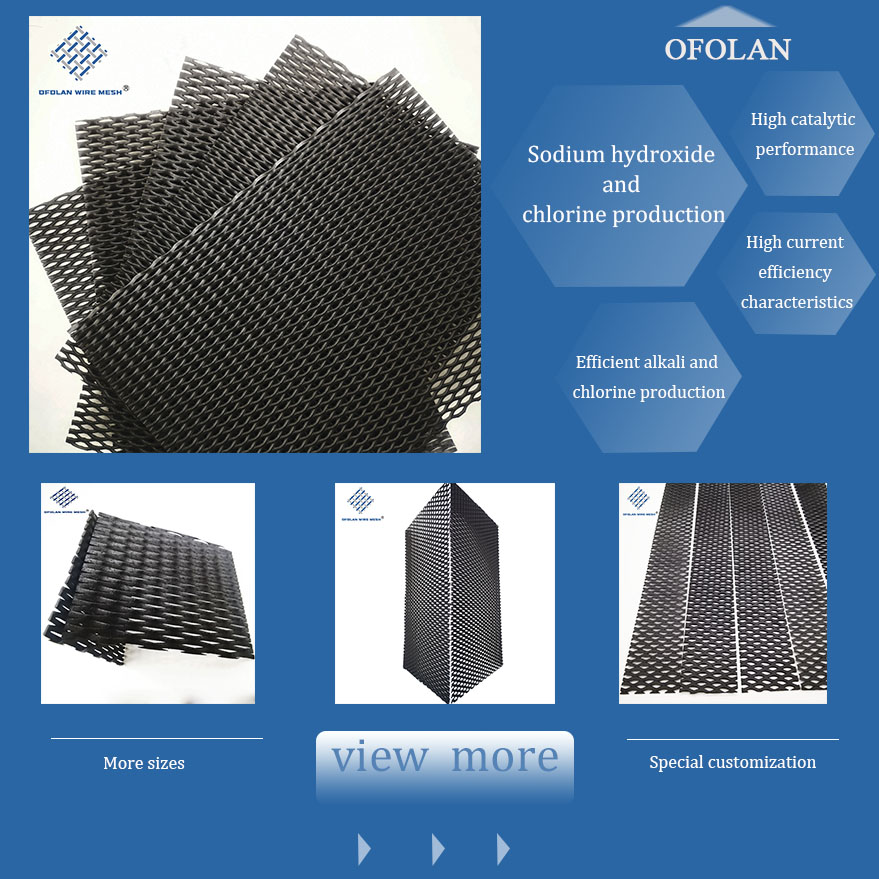

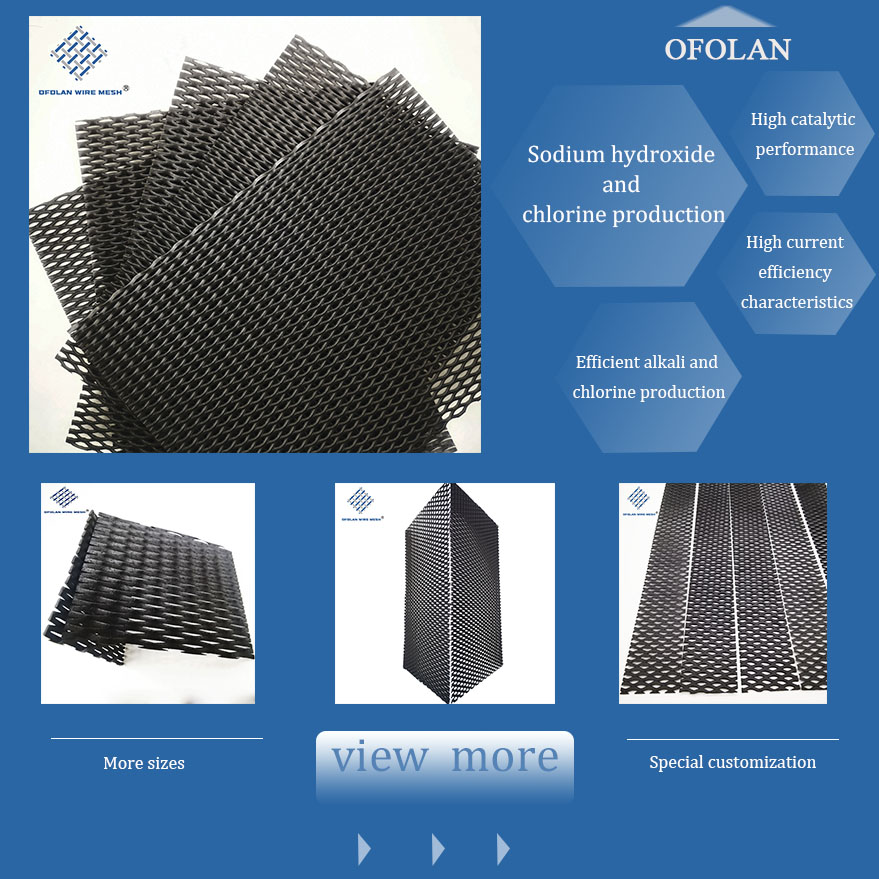

400x300mm Ruthenium Iridium Coated Titanium Mesh Ru-Ir-Ti Oxide Coating Titanium Anode NaOH & Chlorine Production

$335.00

$350.00

400x300mm Ruthenium Iridium Coated Titanium Mesh Ru-Ir-Ti Oxide Coating Titanium Anode NaOH & Chlorine Production

Ruthenium-Iridium / Iridium-Tantalum Coated Titanium Mesh Product Description (Condensed)

| Item | English Description |

| Product Name | Ruthenium-Iridium Coated Titanium Mesh; Iridium-Tantalum Coated Titanium Mesh |

| Base Material | Pure Titanium Mesh (TA1, TA2, Gr1-Gr2, purity ≥99.6%) / Titanium Alloy Mesh (Gr5, Gr7) |

| Coating Composition | - Ruthenium-Iridium (Ru-Ir) Coating: Typical ratio (e.g., Ru:Ir = 7:3, 6:4) - Iridium-Tantalum (Ir-Ta) Coating: Typical ratio (e.g., Ir:Ta = 8:2, 7:3) |

| Manufacturing Process | 1. Titanium mesh pretreatment (acid pickling, sandblasting) to enhance adhesion 2. Coating preparation (thermal decomposition, sputtering, or sol-gel method) 3. High-temperature sintering (400-600℃) for stable coating bonding |

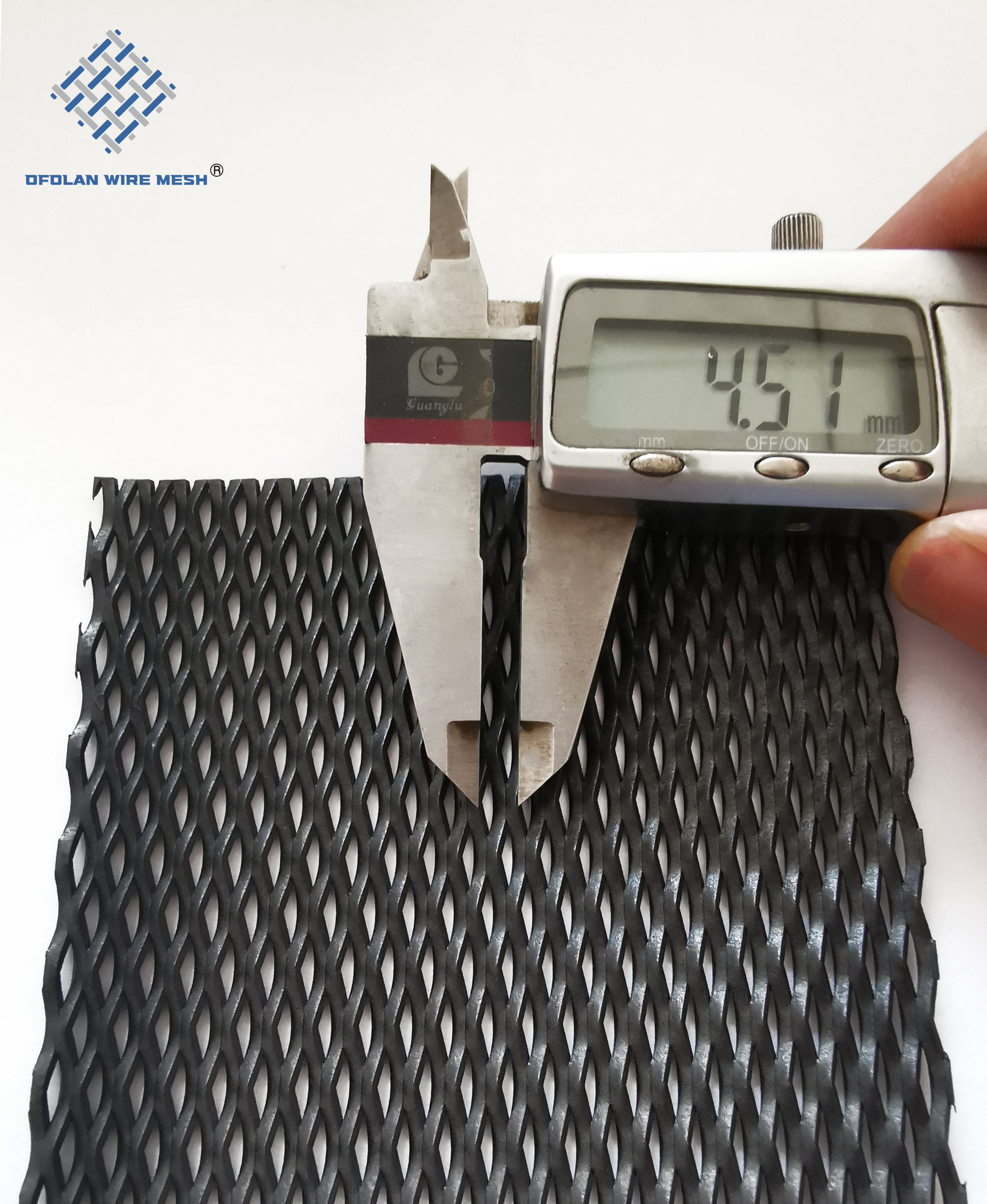

| Core Properties | - Corrosion Resistance: Ru-Ir coating resists chlorine corrosion; Ir-Ta coating resists oxygen corrosion (suitable for strong acid/alkali electrolysis) - Catalytic Activity: High catalytic efficiency for gas evolution (Cl₂, O₂) - Durability: Coating adhesion ≥5MPa, long service life (5000-10000 operating hours) - Conductivity: Low surface resistance, compatible with high current density (100-500 A/m²) |

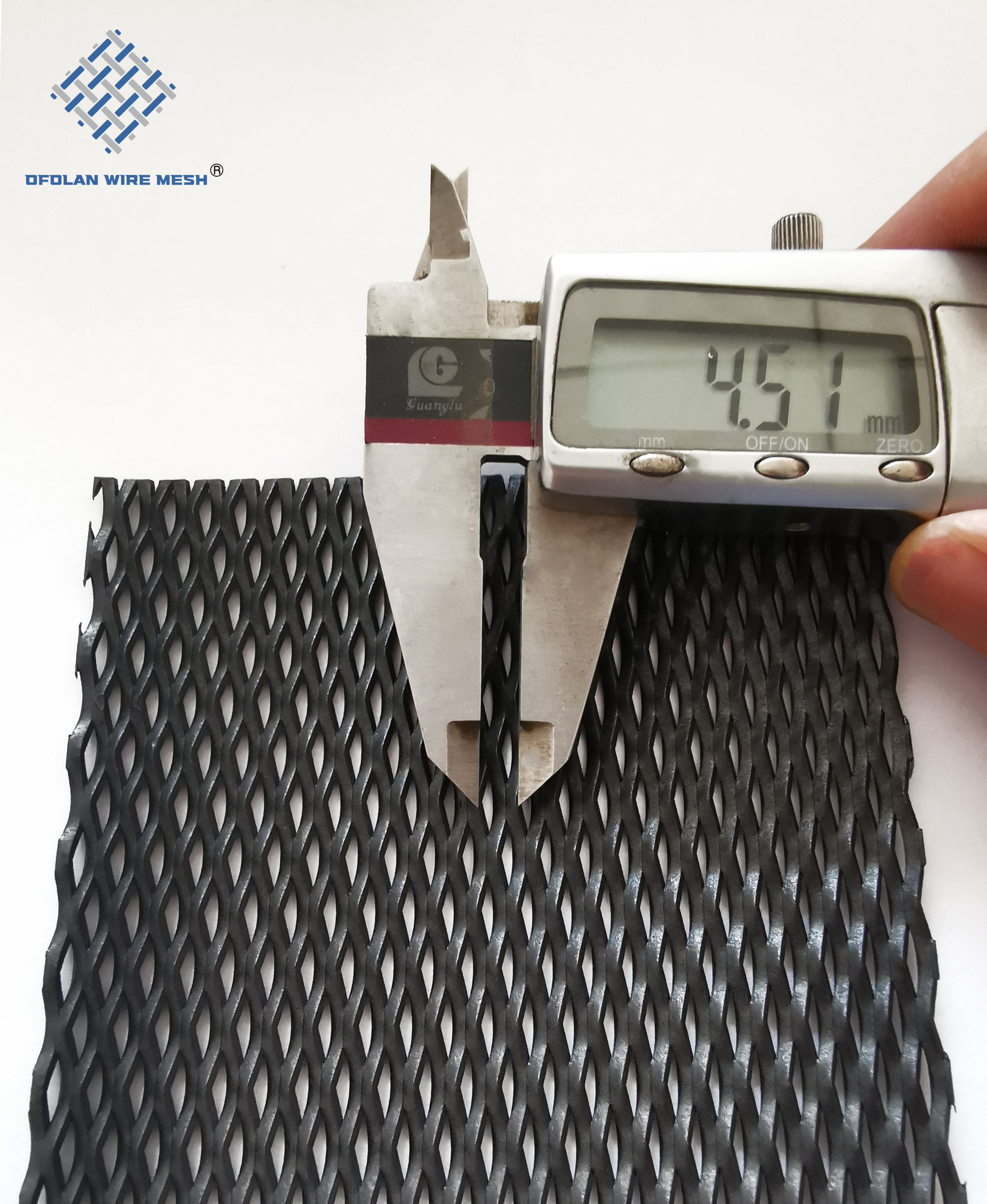

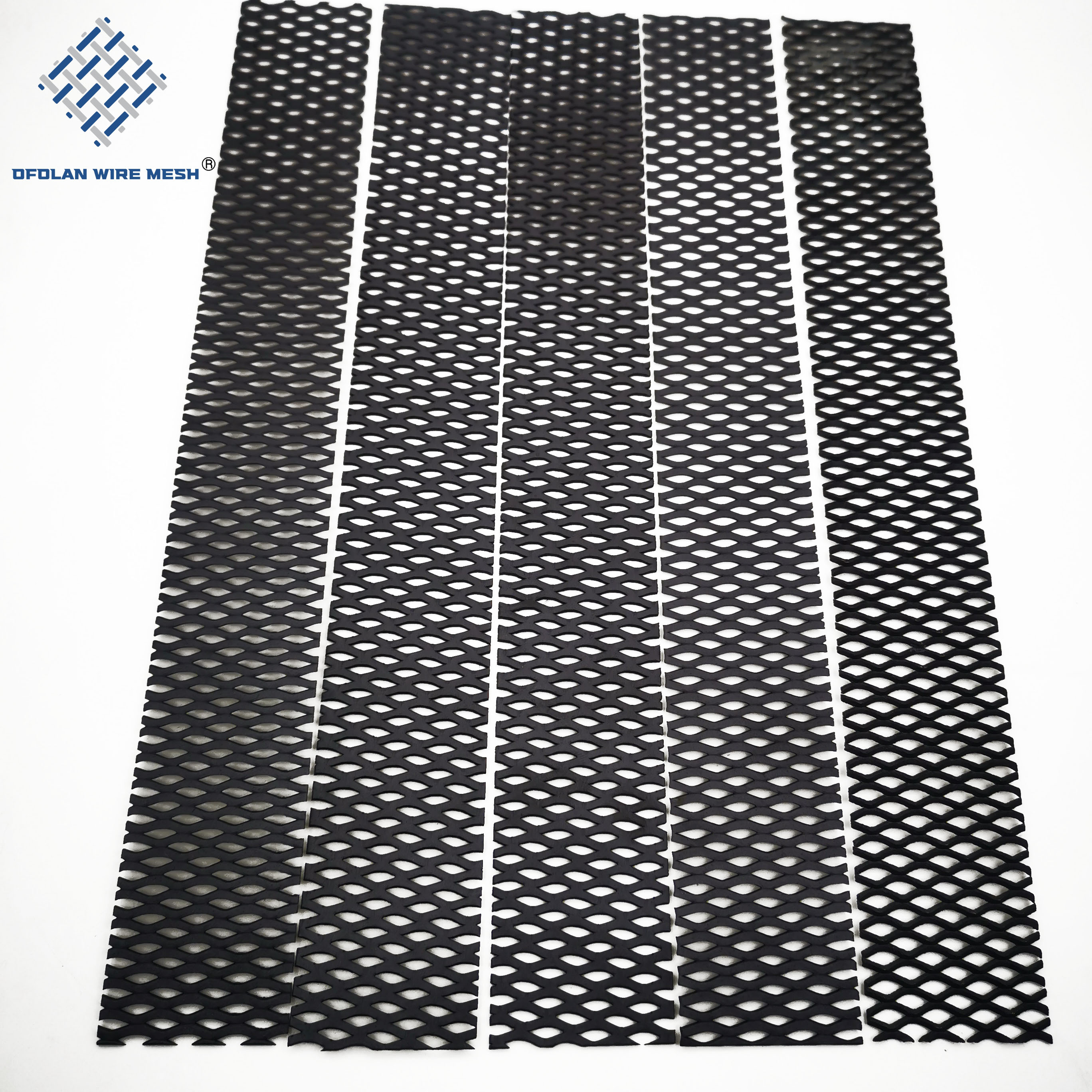

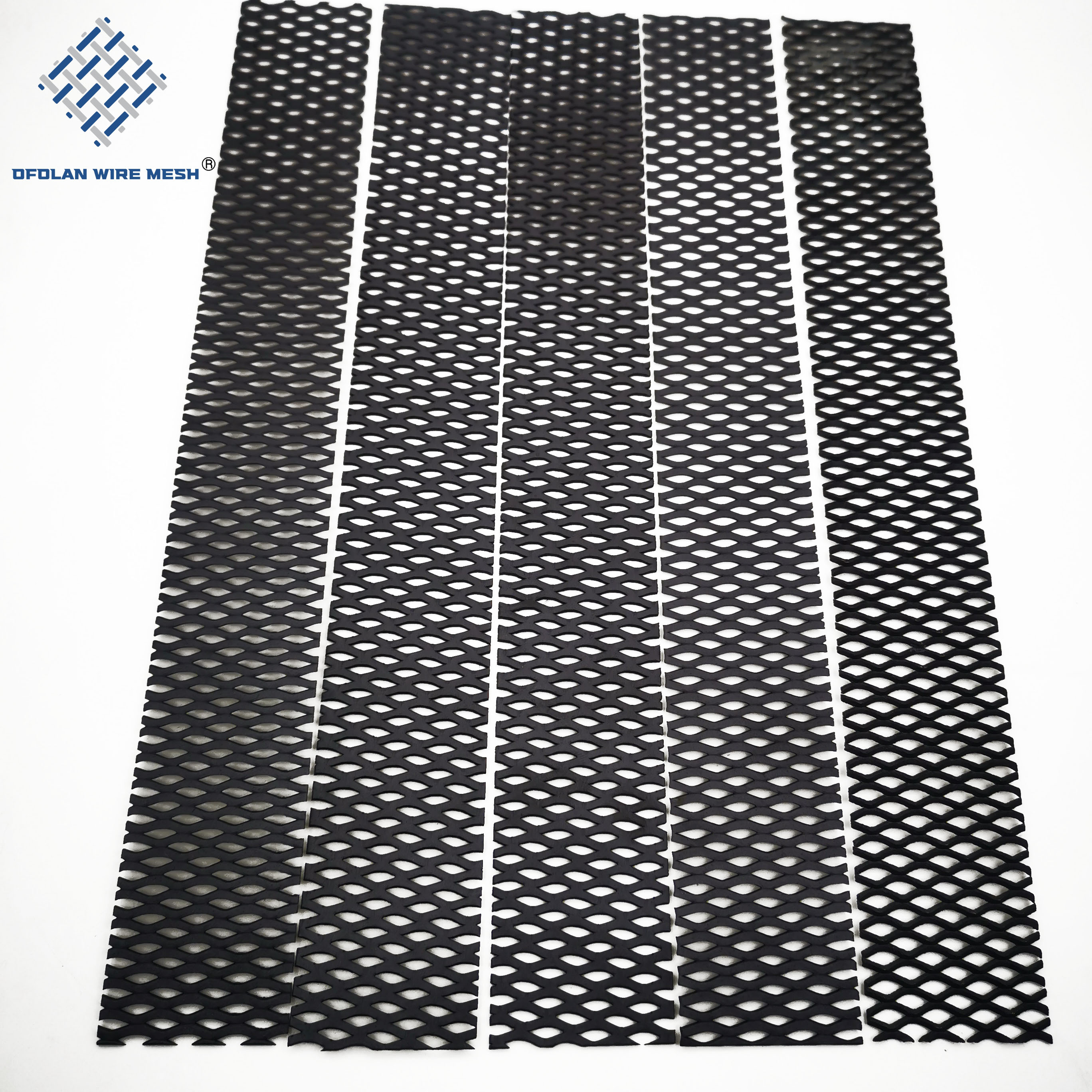

| Key Specifications | - Titanium mesh: Thickness 0.1-2mm, hole type (diamond/round/hexagonal), hole size 0.5-10mm - Coating thickness: 1-10μm - Surface: Uniform coating, no peeling/cracking |

| Applications | - Electrolysis: Chlor-alkali industry (Ru-Ir coated for NaCl electrolysis anodes), PEM electrolysis hydrogen production (Ir-Ta coated for oxygen evolution anodes), non-ferrous metal electrolysis - Water Treatment: Electrolytic oxidation of wastewater (organic pollutant degradation) - Electroplating: Inert anodes for hard chrome plating, nickel plating - Energy: Electrochemical energy storage device electrodes |

| Customization | Customizable titanium mesh size/hole type, coating composition ratio, coating thickness |

No data

400x300mm Ruthenium Iridium Coated Titanium Mesh Ru-Ir-Ti Oxide Coating Titanium Anode NaOH & Chlorine Production

$ 335.00 $ 350.00

Shipping Fee:$20.00

1/3

400x300mm Ruthenium Iridium Coated Titanium Mesh Ru-Ir-Ti Oxide Coating Titanium Anode NaOH & Chlorine Production

$335.00

$350.00

400x300mm Ruthenium Iridium Coated Titanium Mesh Ru-Ir-Ti Oxide Coating Titanium Anode NaOH & Chlorine Production

Ruthenium-Iridium / Iridium-Tantalum Coated Titanium Mesh Product Description (Condensed)

| Item | English Description |

| Product Name | Ruthenium-Iridium Coated Titanium Mesh; Iridium-Tantalum Coated Titanium Mesh |

| Base Material | Pure Titanium Mesh (TA1, TA2, Gr1-Gr2, purity ≥99.6%) / Titanium Alloy Mesh (Gr5, Gr7) |

| Coating Composition | - Ruthenium-Iridium (Ru-Ir) Coating: Typical ratio (e.g., Ru:Ir = 7:3, 6:4) - Iridium-Tantalum (Ir-Ta) Coating: Typical ratio (e.g., Ir:Ta = 8:2, 7:3) |

| Manufacturing Process | 1. Titanium mesh pretreatment (acid pickling, sandblasting) to enhance adhesion 2. Coating preparation (thermal decomposition, sputtering, or sol-gel method) 3. High-temperature sintering (400-600℃) for stable coating bonding |

| Core Properties | - Corrosion Resistance: Ru-Ir coating resists chlorine corrosion; Ir-Ta coating resists oxygen corrosion (suitable for strong acid/alkali electrolysis) - Catalytic Activity: High catalytic efficiency for gas evolution (Cl₂, O₂) - Durability: Coating adhesion ≥5MPa, long service life (5000-10000 operating hours) - Conductivity: Low surface resistance, compatible with high current density (100-500 A/m²) |

| Key Specifications | - Titanium mesh: Thickness 0.1-2mm, hole type (diamond/round/hexagonal), hole size 0.5-10mm - Coating thickness: 1-10μm - Surface: Uniform coating, no peeling/cracking |

| Applications | - Electrolysis: Chlor-alkali industry (Ru-Ir coated for NaCl electrolysis anodes), PEM electrolysis hydrogen production (Ir-Ta coated for oxygen evolution anodes), non-ferrous metal electrolysis - Water Treatment: Electrolytic oxidation of wastewater (organic pollutant degradation) - Electroplating: Inert anodes for hard chrome plating, nickel plating - Energy: Electrochemical energy storage device electrodes |

| Customization | Customizable titanium mesh size/hole type, coating composition ratio, coating thickness |

No data

400x300mm Ruthenium Iridium Coated Titanium Mesh Ru-Ir-Ti Oxide Coating Titanium Anode NaOH & Chlorine Production

$ 335.00 $ 350.00